In 2022 a mandate was announced that any new school buses in New York schools would have to be zero emissions by 2027; and by 2035, the school bus fleet statewide must be all-electric. In conjunction with the new electrical vehicle bus mandate, the new transportation facility is poised to accommodate the evolving landscape of electric buses, showcasing the district’s proactive approach to embracing clean and cutting-edge technologies. Fueled by a comprehensive vision, Lake George Central School District’s capital project is a testament to the safety of our students and the broader transformation taking place across the state.

District Votes YES to Capital Project

In December, 2022 voters approved the Transportation Facility project. The new facility is not anticipated to be built and ready for use until the fall of 2025, and due to this timeline there are no immediate plans for the existing transportation building. Below is an updated timeline for the Transportation Facility project:

- Fall 2023- Programming and Design Process

- Winter 2023- Submission to SED

- Spring/Summer 2024- Expected SED Review and Approval

- Fall 2024- Proposed Bid Date

- Winter 2025- Contract Awards

- June 2026- Construction Substantial Completion

- August 2026- Project Close-Out

Electric Vehicle Information

Electric school buses can help school districts save money

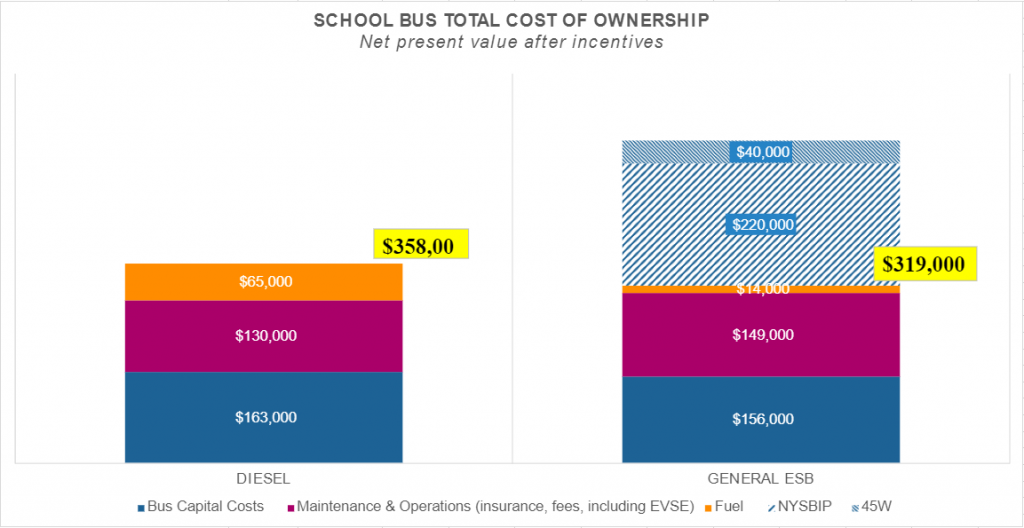

There are record levels of funding and financing available to help offset the costs of electric school buses. Electric school buses have lower maintenance and fuel costs over time – and research suggests that compared to a new diesel-burning school bus, a new electric school bus can save an average of $6,000 every year on operational expenditures, depending on factors such as location, the equipment being used and other operational conditions. When paired with incentives and available funding options like the Clean School Bus Program, the total cost of ownership (TCO) of electric school buses can be hundreds of thousands of dollars lower than for diesel-burning school buses. As competition and technological advances drive the upfront purchase price of ESBs down over time, the total unsubsidized cost of owning an ESB is expected to be on par with the total cost of owning a diesel-burning school bus by the end of the decade.

Below are just some of the funding sources Lake George Central School District plans on using for the current and future financing of electric vehicles.

Electric school buses offer cleaner air and healthier rides

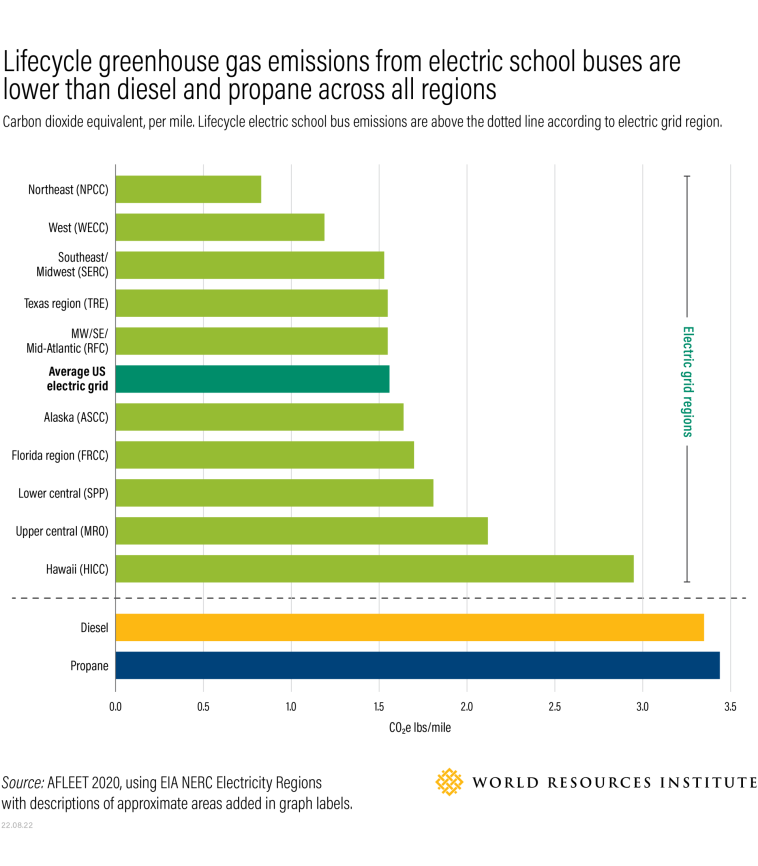

Electric school buses produce the lowest levels of greenhouse gas emissions of any school bus type, even when accounting for emissions generated in production of the electricity used to power the buses. They also have zero tailpipe emissions of harmful air pollutants and the lowest greenhouse gas emissions of any school bus type, even when accounting for emissions from the generation of electric power. Electric school buses are the only school bus option with zero tailpipe emissions. This reduces student exposure to harmful pollutants like nitrogen oxides, which contribute to respiratory and heart disease. Diesel, propane and compressed natural gas (CNG)-burning buses all emit air pollutants that students should have limited exposure to. Electrifying the full U.S. school bus fleet by 2030 would reduce greenhouse gas emissions by 9 million metric tons per year, the equivalent of taking 2 million cars off the roads. On a lifecycle basis, electric school buses produce less than half the greenhouse gas emissions of both propane and diesel. As renewable energy usage increases on power grids nationwide, emissions related to electric school buses will decrease even more over time, which isn’t the case for fossil fuel-burning buses.

Safety of electric school buses

Electric school buses (ESBs) and chargers include many features that ensure the safety of drivers, maintenance technicians, and other ESB users. This guide explores the safety features of ESBs and chargers, and summarizes best safety practices for drivers, technicians, and first responders.

- Extensive battery testing. ESB batteries must follow globally recognized safety standards that include SAE J2929 and ISO 26262. Additionally, lithium-ion batteries must have UL and UN safety certifications. All standards must be met for a vehicle to be certified for sale.

- Increasingly stable battery chemistry. The chemistry in lithium-ion batteries, which are used in almost all ESBs, is more stable than that of batteries commonly used in EVs. This chemistry enables the battery to operate through long durations of high temperatures, which decreases the chances of fire.

- Substantial battery protection. ESB batteries are housed in a protective casing, which is typically constructed from steel or aluminum and protects the battery cells from mechanical damage, creates an airtight and waterproof seal, cushions battery cells against vibrations, and helps protect other ESB components from battery fires. Fast Facts: NEMA enclosures • NEMA enclosures are rigid casings around chargers designed to prevent electric shock and protect electronics from environmental hazards such as water intrusion. • Your charger installer should note in their contract that they must install NEMA enclosures in compliance with NFPA 70, National Electric Code, which ensures people and surrounding equipment are properly protected against electrical hazards.

- Battery management system. ESB batteries are equipped with Battery Management Systems (BMS), which regulates voltage, temperature, and humidity levels to minimize cell damage and fire risk. In the event of an ESB collision or short circuit, emergency disconnect switches automatically disengage the battery from the high-voltage systems to protect against electrical arcing and reduce fire risk.

- Collision safety measure. ESB batteries are centered under the chassis in the middle of the bus, which creates a lower and more stable center of gravity. This design feature helps prevent damage to the battery from collisions, rollovers, and tipping during sharp turns. Emergency electrical disconnects automatically activate when a collision or short circuit is detected.

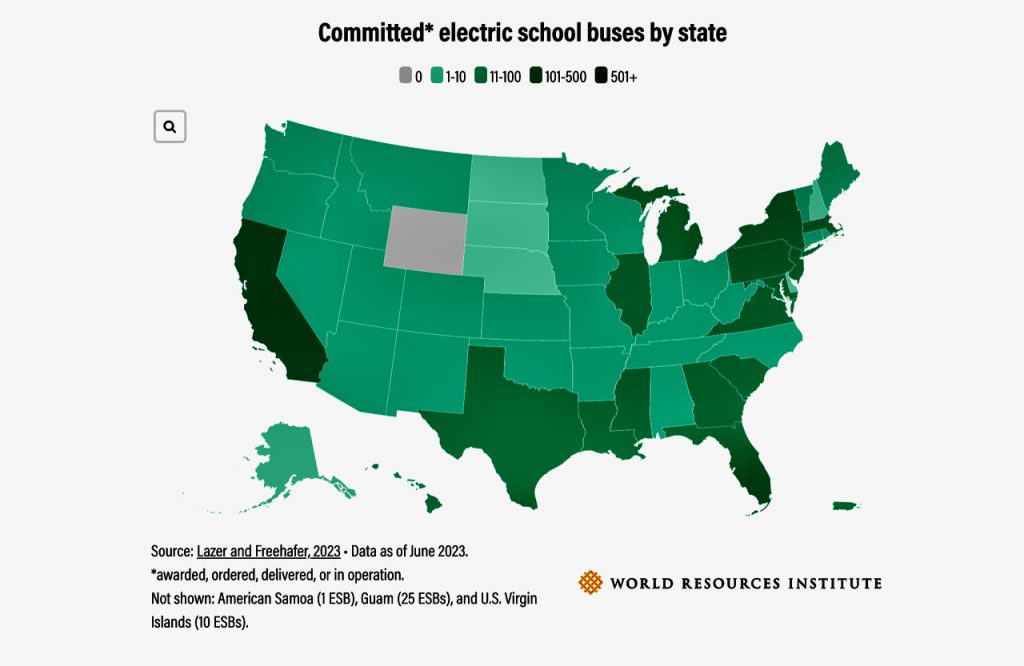

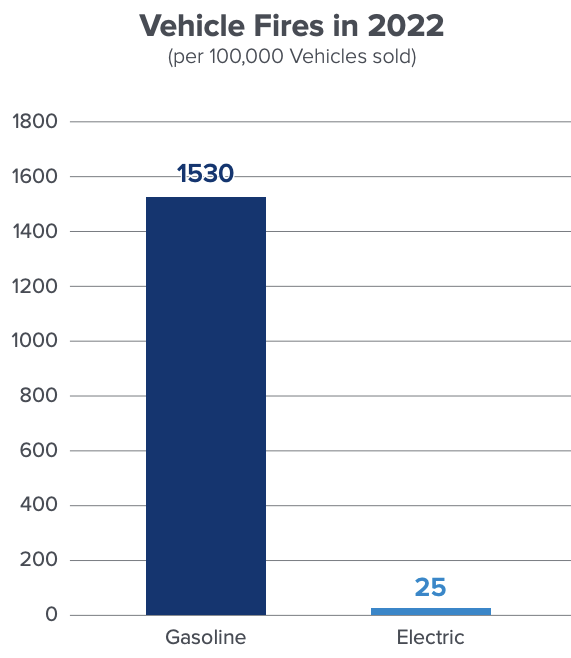

As of early September 2023, there are over 1,200 ESBs deployed in the United States. Out of these, only one bus fire has been reported, and this was attributable to a computer component failure and the fire did not spread to the battery. Upon receipt of an EV bus, Blue Bird manufacture experts conduct a safety training with first responders. Each electric bus has built in safety integrations to alert drivers of battery temperatures ESB and Charger Fire Safety Electric vehicles are far less likely to be involved in fires than those powered by diesel or gasoline. The Federal National Transportation Safety Board (see chart) collects data on vehicle fires and an analysis of that data found that, in 2022, 1,530 gasoline-powered vehicles per 100,000 were involved in vehicle fires while only 25 electric vehicles per 100,000 were involved in fires. The National Fire Protection Association (NFPA) has developed useful resources that can be shared with drivers and other maintenance staff to help prepare for ESB emergencies.

Range and reliability of electric school buses

- Electric school buses are successfully operating in all types of climates and in urban, suburban and rural communities – all while safely and reliably transporting students and giving school districts an opportunity to save on fuel and maintenance costs.

- Electric school buses currently have nameplate ranges of up to 210 miles for Type C buses, and all Type A, C and D buses identified on the market have nameplate ranges of over 100 miles, enough to cover most routes in operation.

Cold weather performance

- Electric school buses are successfully operating throughout the country, including in locations with extreme cold weather. That’s because today’s electric school buses — equipped with powerful batteries and thermal management systems — are designed to handle the tough cold and can be deployed successfully with proper planning, including route selection, charging scheduling and pre-heating.

- In a yearlong state-run study, Vermont found that in Barre Union Unified School District, despite harsh mountain winters, the electric school buses performed well on daily routes.

- Garretson School District in South Dakota found that their three electric school buses are running strong in the winter in below-zero temperatures. The buses can ravel up to 125 miles in optimal conditions and Garretson’s longest route is 47 miles, so the range lost in cold temperatures hasn’t been a concern when transporting students to and from school.

- Morris Area Schools in Minnesota are also happy with their electric school bus results. The buses have operated through several winters and while they lose about 10-15% of their battery capacity, including when temperatures drop below zero degrees Fahrenheit, they have been able to keep routes going. The superintendent is pleased with fuel savings, noise reductions and alignment with a community-wide focus on clean energy.

- West Grand County School District in Colorado have operated an electric school bus since 2020 despite being located in “one of the coldest places in the state.” Morning winter temperatures range between minus 30 degrees and 5 degrees Fahrenheit. The director of transportation says the electric school bus performs extremely well, and that it also is the best bus in their fleet with much lower operating costs than their diesel-burning buses.